About Us

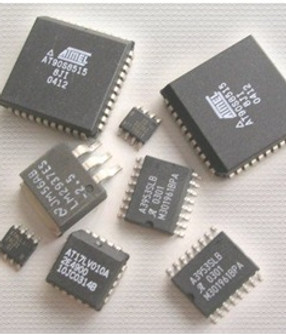

The inner systems was founded in the year 1996 as a PCB design consultancy services in Bengaluru, Karnataka, India, and from then we have evolved in different dimensions to serve our esteem clients in India and overseas. We provide services in Embedded Design Services, PCB Design, Rigid Flex PCB Fabrication, PCB Assembly, Mechanical Design of enclosures and sales and import of Electronic Components. We have extensive experience in the respective fields to support our clients in their need. Now all the services can be availed at one stop from a single source.

Electronics Technology have grown so much that even the PCB designs have to play a very important role in bringing up quality products. At present PCB designs have become more complex in terms of technology, high speed clock signals and trace density. PCB is the one of the most important components in any electronics product. A decade ago the manufacturers were unaware of importance of PCB design. But with advancement of Technology the PCB design is the topmost priority to achieve a good functional product. If PCB is designed in primitive way, it is most likely to fail in every aspect of functionality. It is very much necessary for any developer to consult the professional PCB designers to bring up perfect products. You can not compromise even PCB Fabrication, PCB assembly and Enclosure.

And we are here to provide you the total solution to bring up your product with full confidence. Since we have vast experience in the field of PCB Design, Board Assembly, Design of Electronics Enclosures, we assure all the clients with full satisfaction. We can provide the complete solution from PCB design to the enclosure design. We also take up the part of the projects like PCB design, PCB Fabrication, Board Assembly, Enclosure design etc. individually. If the product is designed in crude fashion the product may not be marketable. Before the product design is finalised be aware of your PCB design done and manufactured as per the specifications required. Inner Systems is committed to deliver quality design services as per the industry standard. PCB fabrication is one more part of our services offered to you as per the manufacturing specifications adopted.

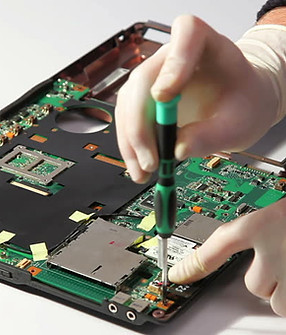

We understand in depth the requirements needed for manufacturing of PCB with various specifications, such as IPC standards, Tooling specifications, dielectric material, dielectric thickness, coper thickness, Copper purity, Surface Finish, flammability requirements etc. The PCB assembly is of a next stage of Electronic production services available to our customers. The various stages in the PCB assembly process including adding solder paste to the board, pick and place of the components, soldering, inspection and quality test. All these processes are required, and need to be monitored to ensure that product of the highest quality is produced. Once the board is assembled and tested, it is time to package in proper enclosure. Aesthetic part of enclosure is a very essential for marketability. Let us do your all design work for you. If you give us all the responsibilities and you will save a lot of time and money. Below is the list of all services available to you. If you need any service that will benefit you, Please Contact us.